We’re proud to highlight one of our successful collaborations with Harper Trucks, a valued partner from the United States with whom we have built a long-standing relationship based on mutual trust, technical expertise, and consistent quality.

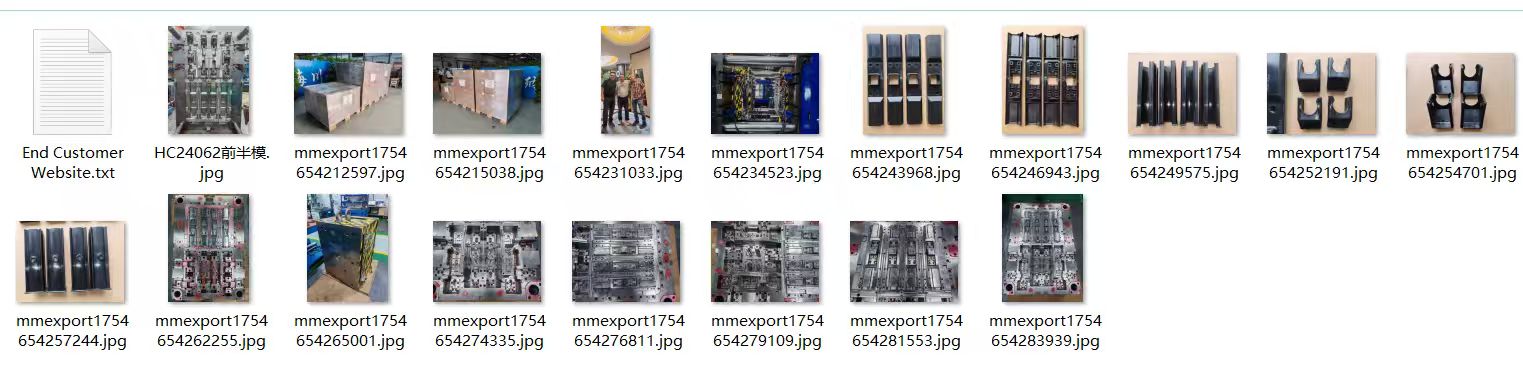

Recently, representatives from Harper Trucks visited our facility here in China, strengthening our partnership through direct communication and on-site inspection.

This project involved the development of four custom precision molds with multi-cavity configurations (4 + 4 + 4 (4) cavities) for key plastic components, including:

Block B Large

Block B Large Extended

Caster Bracket Cap

JDC Slide Tube Plastic

Each mold was designed and manufactured to meet strict standards for functionality, durability, and production efficiency. Using YUNGSOX® PP 5090T material and high-quality surface finishes (MT-11530 cavity and SPI C-1 core), we ensured every part achieved precise dimensions, tight tolerances, and excellent visual appearance.

By sharing this project, we demonstrate our ongoing capability in delivering complex, multi-part mold solutions with advanced cavity design that combine engineering precision with production reliability — a commitment we have maintained through our long-term collaboration with Harper Trucks.

If you’re looking for a trusted partner for your next mold development project, we’re ready to support you — from concept to completion.

Related Tags :